Blow moulding machine upgrade using B&R

Seamless Integration of complex extras

In our latest onsite upgrade KlareTech went all the way.

This dual carriage extrusion blow moulder had every possible additional feature - Takeout robots, In-mould labelling robots, hydraulic scrap remover and needle-blow. All of these features were seamlessly integrated into the B&R blow moulding control platform running on a Power Panel 400 embedded HMI/PLC with X20 IO.

An 8-layer parallel control sequence means that every movement is adjustable to ensure flexibility for handling the most complex tasks.

The below video shows one of the most complicated bottles currently blown in the South African market running smoothly with a cycle time of 14 seconds all controlled with our upgraded system.

Read more: Blow Moulder Upgrade with all the Bells and Whistles

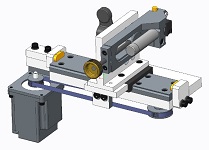

Turnkey machine built to press handles on PET bottles

2700 bottles per hour with a footprint of less than 4 square meters

KlareTech's latest turnkey project is set to become a serial production offering. The handle press applies handles to PET bottles before they are filled at a rate of one handle every 1.33 seconds.

The unique challenges for this machine are feeding the handles in a fast an economically viable way, and providing support to the sidewalls of the bottle so that it doesn't collapse during the application of the handle.

Our unique approach to feeding the handles to the machine from hand-packed cartridges allows handles to be prepared in advance or during operation. An XY stage driven by B&R servo motors gives fast precise positioning of the bottle support and handle press mechanisms in relation to the bottle and allows it to be cleared out of the way of the next incoming bottle at high speeds. Bottles are supported at the strongest part with another unique solution that ensures no load is carried by the sidewalls of the bottle during the handle application.

The machine is controlled using a B&R control system which is completely integrated end-to-end for plug and play maintenance and simple onboard diagnostics.

KlareTech bolt on solution

Speed and Accuracy from B&R stepper motors

Caxton approached us to develop a system to identify a 2mm thick piece of cardboard in a stack of labels based only on a slight difference in colour between the edge of the labels and the edge of the cardboard and then to pneumatically seperate the stack at the cardboard.

The system had to be reliable, accurate, fast, and fit into a small space under an existing machine. It was also necessary for the system to handle different colour labels and cardboard seperators.

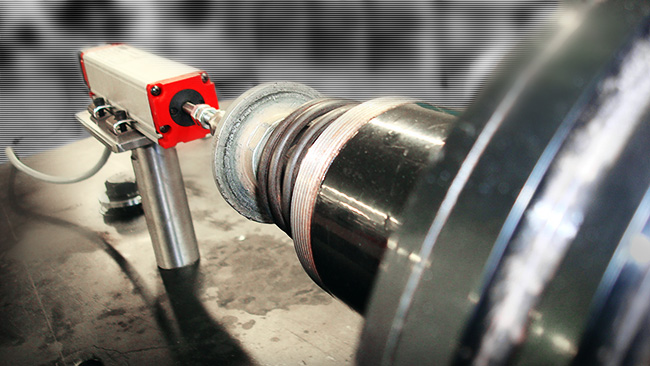

Dual Carriage Extrusion Blow Moulder Upgrade

Fastest possible turnaround with B&R control system

KlareTech recently completed a control system upgrade on an old dual carriage extrusion blow moulding machine.

The upgrade took only 5 days from arrival on site to full production! This super fast turn around time was made possible by the pre-written B&R blow moulding software and embedded control system and HMI combination of the B&R Power Panel range.

The upgrade took only 5 days from arrival on site to full production! This super fast turn around time was made possible by the pre-written B&R blow moulding software and embedded control system and HMI combination of the B&R Power Panel range.

Turnkey test equipment by KlareTech

Solenoid test bench

When one of our customers needed to thoroughly test a component of their machine before using it the field they turned to KlatreTech to find the solution.

Using a B&R X20CP1486 PLC and a KlareTech custom-built 550VDC drive we were able to create a system that not only monitored various elements of the solenoid such as temperature in several different places on the solenoid as well as stroke length, stroke time, power consumption and current drawn with each activation of the solenoid but also provided the control for the solenoid to simulate field activities.