ACOPOS P3

ACOPOS P3

More than ever before, machine and system manufacturers are being confronted with demands for increased productivity and availability. At the same time, pressure is constantly building to reduce the manufacturing costs for production machines. The new servo drive generation from B&R was designed to meet these challenges.

Increased Productivity

To strike a balance between increased productivity and decreased energy consumption with a smaller footprint, machine manufacturers are shifting to lightweight construction. This reduces the masses being moved – and thus the moment of inertia – in addition to making the machines less rigid and more elastic. Virtual sensing makes it possible to control these elastic systems while retaining a high level of quality without having to use additional position sensors at the process intervention point.

Encoderless control

The ability to use virtual position encoders eliminates the need for a position encoder, cable and evaluation unit in the servo drive, reducing the number of components while increasing availability at the same time.

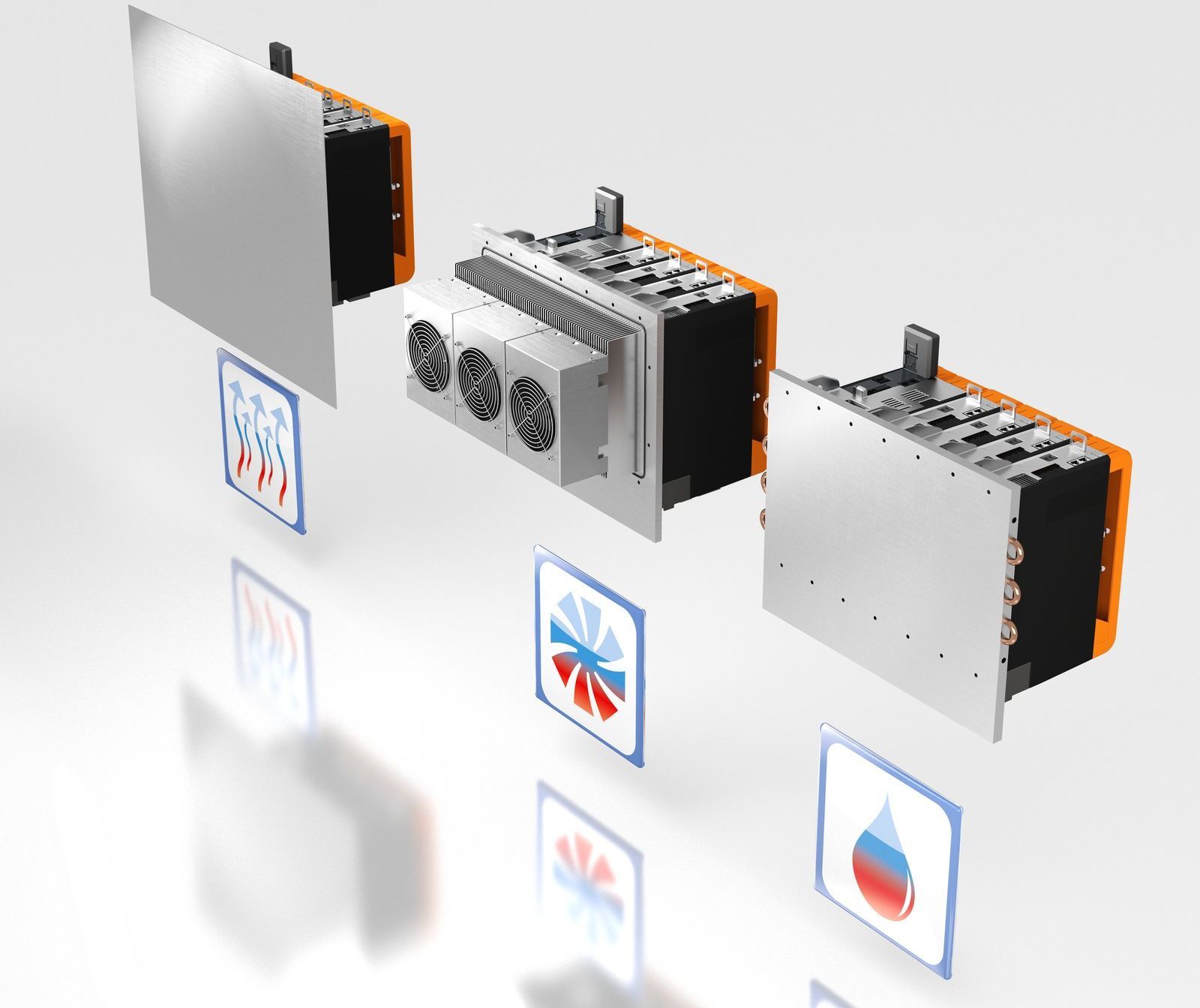

Modular cooling conceept for ACOPOS P3

The ACOPOS P3 servo drive is now also available with feed-through heat sink or cold plate cooling. This reduces the use of fans and air conditioners in the control cabinet or, ideally, eliminates them altogether. Operation and maintenance costs are reduced.

Some key features

Some key features

- No additional maintenance required

- No additional fans in the control cabinet

- The right solution for every machine

69% smaller footprint with maximum power density

The ACOPOS P3 is offered as a 1-, 2- or 3-axis drive and covers a power spectrum ranging from 0.6 to 18 kW, or 1.6 to 44 amps. With a housing as compact as a conventional 1-axis drive, the 3-axis drive reduces cabinet space requirements by 69%.

Innovative drives with an exceptionally small footprint

With the ACOPOS P3, B&R is setting new standards for motion control. This 3-axis servo drive offers a power density of 4 amps per liter, making it one of the most efficient servo drives with integrated safety functions on the market. It also offers unrivaled dynamics and precision, with a sampling time of just 50 µs for the entire controller cascade.

More than ever, machine and plant manufacturers are confronted with demands for higher productivity and increased availability. At the same time, the manufacturing costs for the production machines need to be reduced. The new generation of servo drives from B&R meets this challenge.