ACOPOStrak

ACOPOStrak

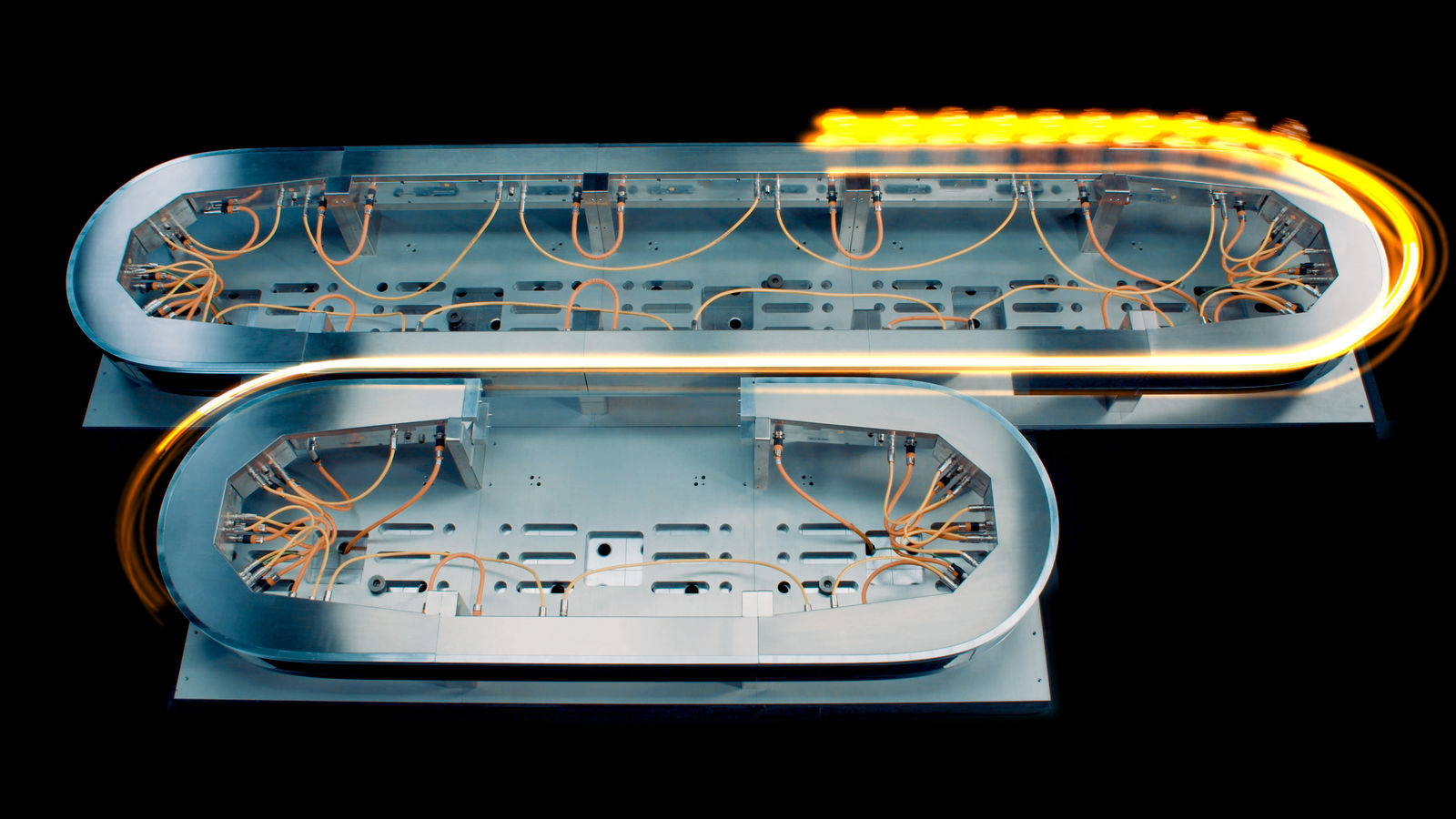

ACOPOStrak is a revolution in adaptive manufacturing. This highly flexible transport system extends the economy of mass production down to batches of one. Parts and products are transported quickly and flexibly from processing station to processing station on independently controlled shuttles.

ACOPOStrak is a generational leap in intelligent, flexible transport systems. Its absolutely unique design delivers decisive technological advantages for adaptive, connected manufacturing. Produce small batches efficiently and benefit from the higher margins of personalized products. Extend your digital transformation to include motion control and mechanical design.

Smart-factory motion control brings you key advantages: maximum availability, high-speed transport and positioning, rapid changeover and fault-tolerant high quality. ACOPOStrak boosts your overall equipment effectiveness (OEE), multiplies your return on investment (ROI) and accelerates your time to market (TTM).

To see the ACOPOStrak in action please visit - https://www.youtube.com/watch?v=NDT0cJW6vEw

Scalable machinery

ACOPOStrak can be expanded flexibly by adding track modules and processing stations. This in turn gives your machine the scalability to adapt to changes in demand. That's true investment security that multiplies your returns. ACOPOStrak gives you more output per square meter of machine footprint.

Highly profitable, even in mass customization

Individualized processing, zero-downtime changeovers and modular track segments that morph into any form: ACOPOStrak has everything it takes to enable mass customization in batches of one. It will boost your OEE, accelerate your ROI and shorten your time-to-market.

Maximum productivity

Compose custom sets in real time

ACOPOStrak diverters let you group products into custom sets – in real time and with no changeover. Create custom six-packs of different beverages, for example.

Maximum production speed

The diverters pass shuttles from track to track reliably at full speed without any compromise in productivity.

Sorting on the fly

ACOPOStrak diverters allow you to sort out individual defective products as soon as they are identified, saving the additional waste of further processing – including primary and secondary packaging materials. This opens up new dimensions of resource efficiency and boosts the quality factor of your OEE.