Injection Moulding

Here at KlareTech we have done many injection moulding machine upgrades all across Africa in some of the biggest plastic industries around.

Some Examples of Injection Moulding Projects we have been involved with.

Complete control system upgrade of any injection moulding machine installed for multiple customers in Africa.

Injection Moulding Machine Upgrades

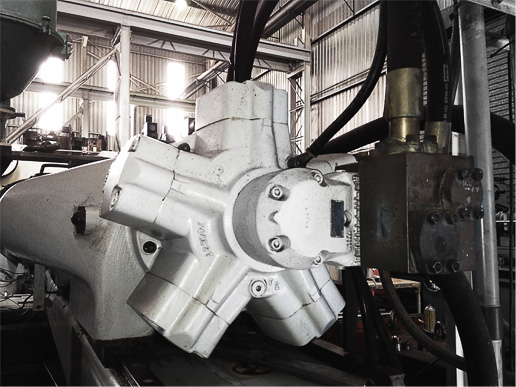

B&R SmartMould

Complicated electrical control systems, although ruggedized to varying extents, are usually based on similar technology to PC's and expecting them to perform day after day in the often harsh production environment for years on end is of course, unrealistic.

Complicated electrical control systems, although ruggedized to varying extents, are usually based on similar technology to PC's and expecting them to perform day after day in the often harsh production environment for years on end is of course, unrealistic.

It is normal for the downtime on machines with electronic control systems to increase exponentially as a function of time due to the decreasing availability of components, greater difficulty in troubleshooting as problems become more stochastic, complex and interlinked and the increased chance of failure of these components due to years of daily wear and tear. These challenges are compounded by the fact that older components generally become more expensive as the volumes of their global use decrease. Constantly repairing these systems is akin to trying to repair a 10 year old computer at an ever increasing price with ever worse reliability and functionality as the end result. As with the computer it makes much more sense to simply replace the control system with a new one.

Succesful local installations include machines for AstraPak, Venture and Boxmore.