Pharmaceutical packaging machine using B&R

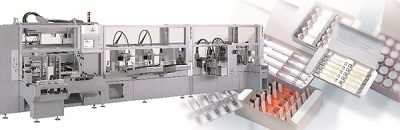

The NeoTOP 804 from Dividella prepares up to 80 boxes per minute, inserting up to four separators that hold vials and syringes safely in place.

How do you package pharmaceutical products such as needles, vials, flasks and blisters at maximum speed without damaging them? This simple question has spurred development at Dividella AG for over 40 years. The best answer yet is the NeoTOP 804, which opens cardboard blanks and folds the separators that are then inserted and glued in place. Performed manually, this process takes around 60 seconds per package – in which time the NeoTOP 804 can finish around 80 of them. The packages can be up to 240 x 170 x 70 millimeters in size and hold up to 1,600 tubes, flasks or cartridges. When packaging syringes, needles and certain other objects up to 40 x 190 x 40 millimeters, output can even be tripled.

New flexibility with a new platform

Every packaging machine that leaves Dividella's floor is one-of-a-kind. Although the platform concept defines the order of processes – place, check, glue, insert, fill, label, fold and seal – each application's unique requirements determine how each step is implemented. To accomplish this without exploding development costs, Dividella takes a decidedly modular approach. "On average we adapt about 20 percent of each machine to the user's requirements. The rest is all standard solutions," says Marc Bachmann, COO at Dividella.

The most significant adaptations are typically to the module that folds the separators that will later hold the vials, flasks and syringes safely in place. "Preparing the boxes is relatively straightforward. Folding and inserting the separators, on the other hand, requires a lot more detail and customization," explains Patrick Marchion, mechanical engineer at Dividella. "Since the construction of the separators depends on the shape of the product, solutions here need to be much more flexible. This applies not only to the tools that shape the inserts, but also to the method by which they are secured in the opened box. While the separator for 'Product A' may only need a 5 millimeter strip of glue, the larger 'Product B' may completely exhaust the maximum 200 milliseconds provided for this process."

Digital line shaft

This range of requirements demands a flexible solution. Dividella needed to come up with a plan that would not only satisfy safety requirements, such as ensuring that inserted products are not damaged, but also permit maximum processing speed. One of the challenges was the vacuum used to remove boxes from the feed and hold them during processing. This tool is not available in real time since there is an interval between when the box is picked up and when the product is secured, the duration of which depends on the size and weight of the box. In the machine's predecessor, Dividella mirrored these processes in a mechanical line shaft – an approach that stood in direct conflict with the goal of modularity. So when B&R suggested implementing this line shaft in virtual form within the controller, Dividella was onboard in no time. This virtual line shaft is now the master on which all other processes are based, which delivers decisive advantages. If it turns out that the box needs to be picked up sooner while the machine is being calibrated, it is extremely easy to simply adjust the respective angle in the software.

"Controlling the machine with the new HMI is a huge step forward," praises Bachmann. Since the stepper motors were replaced by servo motors with absolute encoders wherever possible, setting up the packaging machine's 120 axes, which communicate via POWERLINK with a cycle time of 1.2 milliseconds, is fast and reliable. "We just turn the axes to the desired position and then 'teach-in' the respective pick-and-place values," explains Patrick Marchion. Personnel from B&R are there to help with any questions regarding the control and motion technology being used. This consistency helps avoid communication problems. The new HMI does more than just streamline commissioning; it also speeds up the process of changing over to different packaging types. In less than 30 minutes, a new batch is ready for processing.

|  |

| 35 ACOPOSmulti and 26 ACOPOSmicro drives control the 120 axes in the field and make the NeoTOP 804 a flexible packaging force to be reckoned with. | COO Marc Bachmann and mechanical engineer Patrick Marchion (right) use B&R components to design a machine with maximum modularity. |

|  |

| 30 X20 SafeIO modules monitor all gates and E-stop circuits to ensure maximum safety. | 150 X20 I/O slices collect relevant data in the field to ensure smooth operation. |

Sensors and code readers ensure maximum safety

The process is monitored by various sensors and code readers to ensure that the correct products are used and no products are damaged during packaging. Even the pressure with which vials and syringes are placed in the separators is monitored. The real-time Ethernet POWERLINK bus helps make this possible. Safety is important not only for the packaging, but also for operators and service personnel. That is why 30 SafeIO modules from the X20 system communicate with the controller via the openSAFETY protocol to ensure safe operation of all gates and E-stop switches. A total of 35 ACOPOSmulti and 26 ACOPOSmicro drives, each connected to two motors, make Dividella's NeoTOP 804 a flexible packaging force to be reckoned with. The 120 axes are connected to the controller via five X20 bus controllers. The solution also features 150 I/O slices and 30 SafeIO modules from B&R's X20 system. Process visualization is provided on a B&R Automation PC 810, while two synchronized Ethernet POWERLINK networks communicate with a cycle time of 1.2 milliseconds via an Automation PC 810 running B&R's embedded Automation Runtime operating system.

Patrick MarchionProject Manager at Dividella AG"The integrated development environment provided by Automation Studio was a huge help. We no longer had to manage a hundred different system tools and were able to configure the drives, controllers and integrated safety components with maximum convenience." |