IP69K Servo Motors

Maximum hygiene for foodstuffs and pharmaceuticals

Maximum hygiene for foodstuffs and pharmaceuticals: The new stainless steel servo motors in the 8JSB series feature a hygienic design that allows efficient cleaning in the areas of foodstuffs production and medical engineering. With a smooth surface and IP69K protection, these motors satisfy the requirements of EHEDG, 3A and FDA hygiene standards, making them the optimal choice for harsh environmental conditions or in areas where machines are working with aseptic processes. These motors are characterized by the highest power density in this class.

The construction and design of these motors was undertaken in complete accordance with EHEDG (European Hygienic Engineering and Design Group) directives. The smooth stainless steel housing with a surface finish of less than 0.8 µm, rounded corners and seamless transitions have been designed to eliminate undercuts and protruding screws in order to prevent the collection of contaminants while allowing for simple, safe and efficient cleaning. With a laser-engraved type plate and IP69K protection, these motors are extremely suitable for efficient daily cleaning processes.

The use of B&R's single cable technology with digital feedback reduces the number of feed-throughs to an absolute minimum. Shafts, flanges, housing components and seals satisfy FDA (US Food and Drug Administration) requirements, as evidenced by the housing designed to AISI 316L specifications. Certification in accordance with EHEDG Class 1 allows clean-in-place (CIP) processes, making it the perfect choice when designing open machines.

Top performance and reliability

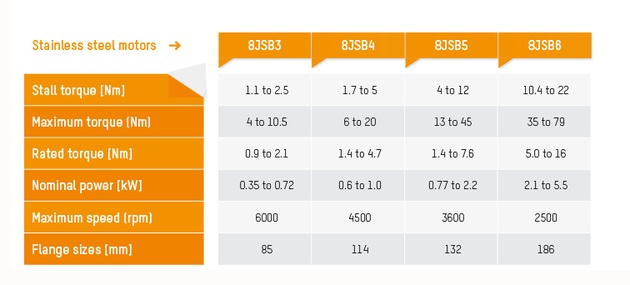

8JSB servo motors are available in 4 different sizes with 3 or 4 different lengths, providing ultimate scalability with respect to torque. Stall torque values range from 1 Nm to 22 Nm; within the extremely large speed spectrum, nominal torque ranges up to 16 Nm at 2,500 rpm. The outstanding speed range of up to 6000 rpm – depending on the size – and the smallest torque derating of under 20 percent underscore the unrivaled position held by these stainless steel motors.

With B&R's single cable design between the motor and robust EnDat 2.2 encoder systems along with automatic pressure compensation, these drives offer even higher operational safety while eliminating outages caused by the internal formation of rust or condensation. Permanently fixed cables are available anywhere from 1 to 15 meters and connected in the control cabinet without interruption. These motors integrate seamlessly in the B&R system environment, with optional safety functionality opening up entirely new possibilities for automation in the foodstuffs and pharmaceutical industries.