Fastest reacting IO with reAction from B&R

reACTION Technology reduces response times in industrial automation applications down to 1 µs. B&R has designed this new ultrafast control technology using standard hardware that can be programmed in accordance with IEC 61131 standards. The result is an immense increase in performance without the downside of additional costs.

In many applications, control speed has a direct impact on product quality. "When forming PET bottles, for example, pressure must be controlled very precisely," explains Anton Meindl, manager of B&R's Controls business unit. "The greater the control precision, the thinner you can make the wall of the bottle." Other examples include the high-precision speed and position control required in injection molding applications. The printing industry is another area where high-speed control functions are essential. "When paper is fed into a machine, the edge needs to be detected at a very fast speed," says Meindl. The list of applications that could potentially benefit from ultrafast response times is virtually endless.

The advantages

|

Conventional I/O technology operates with a minimum response time of around 1 µs. "A microsecond is no longer fast enough for some applications," notes Meindl. "In filling stations for bottled beverages, the control technology needs to process the signal from the fill level sensor faster in order to achieve optimal results."

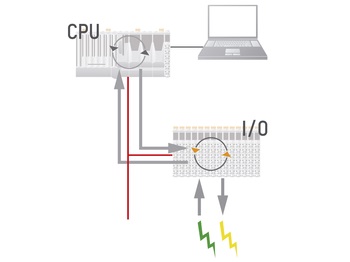

Response times in a conventional solution are influenced by a number of factors such as network performance, or the number of nodes on the network, as well as network traffic and controller performance. With conventional signal processing, the input driver in an I/O module reads the input signal and converts it into a logic signal. This signal is then sent over the network to the central PLC. The PLC processes the signal and sends it back to the module. The output driver once again converts it and sends it to where it is needed. With this approach, there is no way to achieve response times much below the millisecond range.

1 µs response time

"When we developed reACTION Technology, our goal was to accelerate signal processing by integrating as much of it as possible directly into the I/O modules themselves," says Meindl. "At the same time, we wanted to do so without sacrificing the benefits of centralized software management." This new B&R solution cuts the delay between the time the input signal is received and the time the control signal is sent down to 1 µs.

The technology itself is based on I/O modules with integrated FPGA chips. "We used FPGA chips because of their ability to process signals quickly in parallel," explains Meindl. With around 10 connected function blocks, the processing time in the FPGA is around 0.8 µs.

|  |

| reACTION Technology always offers the same ultrafast performance. With signal processing directly in the I/O module, the response time is not influenced by the performance of the network or central controller. | The FPGAs are programmed using the function block editor in B&R's Automation Studio engineering platform using corresponding reACTION libraries |

FPGAs programmed quickly and easily

One challenge B&R's developers faced was the difficulty typically associated with programming FPGAs. "We found a very good solution to this problem," says Meindl. Machine builders can now manage and program FPGAs in the familiar Automation Studio development environment. They do so by developing programs and parameters in the form of IEC 61131 function blocks; communication between I/O and CPU tasks is handled conventionally through the exchange of process variables. Logical operators like AND, OR, XOR and NOT can be used, as can arithmetic operators such as ADD, SUB, MUL and DIV as well as flip-flops, PWM, comparator functions and counters. The connections created with function blocks can be tested just like regular control code. Simulation is possible by executing the modules on the controller. If everything works as planned, the software function is then assigned to the respective hardware component in the Automation Studio hardware configuration.

"Using the same easy approach to software development that B&R customers are accustomed to, reACTION Technology opens up a whole new dimension of speed," says Meindl. In the interest of making applications as universal as possible, function blocks can be loaded to the modules at any time for local execution.

|

| "Distributed automation systems using reACTION Technology are advancing into a whole new dimension of high-speed control." Anton Meindl, Manager of B&R's Controls business unit |

Flexibly faster with reACTION Technology

reACTION Technology integrates signal processing directly in the module, taking the system bus and central controller out of the response time equation. "reACTION Technology always offers the same ultrafast performance," says Meindl. Other solutions on the market either don't offer the same speed or impose unnecessary restrictions on the machine builder with regard to flexibility and programming.

With signal processing using reACTION Technology, the input driver samples the input signal with a resolution of 20 ns and converts it to a logic signal. The FPGA then processes the signal with a cycle time of up to 1 µs. The result is sent back to the I/O module's output driver. The module converts it and generates a physical signal. In other words, the FPGA assumes responsibility for certain control functions and reduces the load on the PLC.

"Since reACTION Technology takes on a significant portion of the processing load, a smaller PLC can be used," says Meindl. This means that machine builders can achieve microsecond control responses using a controller that operates in the millisecond range. "The user now decides the size of processor to be used based on the average load of the application rather than the peak speeds required by a few specific functions," adds Meindl.

|

| B&R offers reACTION Technology for the I/O modules in both its X20 and X67 series (photo), as well as the compact controllers in the X20 system. |

Ultrafast modules, ultrafast control

reACTION Technology is available on both X20 and X67 I/O modules, as well as on the new X20 compact controllers. Three modules with different I/O configurations are available, including two X20 modules (X20RT8001 and X20RT8201) and one X67 module (X67BC81RT).

IP20-rated X20 modules each have four digital inputs with variable input filters and another four configurable digital I/O points with a physical conversion time under 2 µs. The X20RT8201 module has two additional analog inputs (+/-10 V) with 12-bit resolution and a 5 µs conversion time. The X67 module features IP67 protection and offers two 24 VDC digital inputs, three 5 VDC inputs and four configurable I/O points. In addition to the two analog inputs, an analog output (+/-10 V) with 12-bit resolution has also been integrated.

B&R offers reACTION Technology on two compact controller models, the X20CP1381-RT and X20CP1382-RT. These compact controllers are available with 200 MHz or 400 MHz processors. Depending on the variant, up to 256 MB RAM and 16 kB nonvolatile RAM is available. A built-in flash drive is available to store up to 4 GB of application and data storage. The controllers come equipped with Ethernet, USB and RS232 interfaces. In both performance classes, integrated POWERLINK and CAN interfaces are also available.