the Taming of the robot

B&R Automation makes this possible

Industrial robots are seeing increasing use in automated production lines. Until now, however, they have been isolated in cells to ensure the safety of those working in their proximity. Using TÜV-certified function blocks, B&R has now boosted robot safety to a level that allows humans and robots to work hand-in-hand.

Following in the footsteps of their machine colleagues, industrial robots are assuming more and more responsibility in modern production lines. The most widely used type is an articulated arm robot with six electromechanical axes of movement. B&R has taken it upon itself to make industrial robots so safe that they can work hand-in-hand with humans, liberated from the confines of safety gates and enclosures.

The safety requirements for industrial robots and robotic systems and their integration in workplace environments with human workers are defined in ISO 10218, Parts 1 and 2. Among other things, these standards specify the maximum strain to which the human body is permitted to be subjected. These defined upper limits ensure that humans working alongside robots are not exposed to any serious danger. As a general guideline it can be said that a safe limited force of up to 150 N, a safe reduced speed of up to 250 mm/s and automatic stop capabilities ensure that any collisions will be harmless.

TÜV-certified safety at the TCP

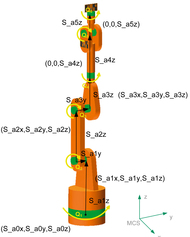

The traverse paths followed by the tools and grippers used by industrial robots to perform their tasks are the product of highly complex axis movement patterns of multi-jointed machines. It is important that safe monitoring of speed accounts not only for each individual axis, but also for the robotic system as a whole, including the tool center point.

The traverse paths followed by the tools and grippers used by industrial robots to perform their tasks are the product of highly complex axis movement patterns of multi-jointed machines. It is important that safe monitoring of speed accounts not only for each individual axis, but also for the robotic system as a whole, including the tool center point.

The first step towards B&R's goal of expanded robot safety was taken in 2011 with the creation of the function SLS at TCP (Safely Limited Speed at the Tool Center Point). This SafeROBOTICS library contains TÜV-certified parameter and function blocks for use in B&R's safe programming environment, SafeDESIGNER.

These function blocks are used to program safety control applications that run on SafeLOGIC controllers. Safety applications read data regarding the status, position and velocity of individual axes and apply transformations to calculate the actual velocity at the tool center point, which in turn is compared with the specified safe values.

SafeMC – Safe Motion Control

On drives equipped with B&R's safe motion control feature, SafeMC, both the reading of the safety-related data and the execution of the safety functions are performed directly on the drive. Data is carried safely over the fieldbus-independent, safety-oriented transfer protocol, openSAFETY.

SafeMC is an integrated standard component of all ACOPOSmulti servo drives from B&R. These drives boast a typical error detection and response time of 7 ms – about a tenth of the time possible with relay safety circuits – which shortens the stopping distance by a factor of 100.

A highly efficient solution from B&R

In the first version of the SafeROBOTICS solution, the software module in charge of monitoring utilized a kinematic model parameter block, which can be configured for all commonly used types of robots. This had a significant disadvantage, however, as the resulting safety application had to be certified separately for each type of robot.

In the first version of the SafeROBOTICS solution, the software module in charge of monitoring utilized a kinematic model parameter block, which can be configured for all commonly used types of robots. This had a significant disadvantage, however, as the resulting safety application had to be certified separately for each type of robot.

To spare its customers this expense and inconvenience, B&R developed a much more efficient solution based on a standardized block of kinematic modeling parameters. The advantage of this approach is clear: The standardized parameter blocks can be applied to any conceivable kinematic chain with up to eleven revolute and prismatic axes, regardless of the specific values they contain.

More freedom, more convenience

The fact that each safety control application only needs to be certified once is only one of the advantages offered by B&R's solution. Transformation parameters also permit modeling of mixed configurations where the robot itself is mounted on a linear portal axis or rotary table.

The fact that each safety control application only needs to be certified once is only one of the advantages offered by B&R's solution. Transformation parameters also permit modeling of mixed configurations where the robot itself is mounted on a linear portal axis or rotary table.

The parameters can also handle constructions where multiple axes are coupled mechanically. In these cases, rotating Axis 4, for example, changes the orientation of Axis 5.

One of the advanced features of SafeROBOTICS is a new function block designed to manage the additional degrees of freedom in complex systems. This function block verifies the plausibility of stored parameters. All of this makes SLC at TCP an easy-to-use safety block – especially when users take advantage of the preinstalled parameter blocks for standard robot types provided by robot manufacturers.

Optimal support for users

Users are free to select whatever type of control works best, be it the robot controller from the manufacturer of the kinematic chain or integration in an overall control system. This is possible thanks to the open and bus-independent safety protocol, openSAFETY. All that is needed is safety-oriented position data and the ability of drives to process safe reactions. Drive components such as ACOPOSmulti with SafeMC are best-suited to these tasks because of their integrated safety functions and increased reaction capabilities.

Since the invention of the electromechanically-driven six-axis articulated robot over 40 years ago, it has never been this easy to allow humans and machines to work together safely.

"Users of SafeROBOTICS don't need to know how the path curves and velocities are calculated. This is all handled by integrated transformation functions. With this optimal support, they are free to focus on their core activities."

"Users of SafeROBOTICS don't need to know how the path curves and velocities are calculated. This is all handled by integrated transformation functions. With this optimal support, they are free to focus on their core activities."

Dr. Gernot Bachler, Motion Research & Development at B&R

Users are free to select whatever type of control works best, be it the robot controller from the manufacturer of the kinematic chain or integration in an overall control system. This is possible thanks to the open and bus-independent safety protocol, openSAFETY.

Users are free to select whatever type of control works best, be it the robot controller from the manufacturer of the kinematic chain or integration in an overall control system. This is possible thanks to the open and bus-independent safety protocol, openSAFETY.