Boosting the sustainability of linear movements

It is becoming harder and harder for pneumatic systems to compete with much more efficient tubular linear motors. In applications with frequent, short linear movements, these motors reduce energy consumption and CO2 emissions by over 90%. NTI and B&R are paving the way for a smoother transition to this more sustainable drive technology. The LinMot linear motors sold by Swiss manufacturer NTI can be controlled directly using ACOPOS servo drives from B&R.

In the musical Starlight Express, electricity wins the race between the various types of drive technology. The machine manufacturing industry shows a similar trend towards fully electric solutions. One of the many reasons for this is the motivation to reduce the energy consumption of production lines. Conventional approaches to improving energy efficiency have already harvested all the low-hanging fruit, however.

The efficiency that remains to be gained through improvements to standard drive technology represents only a small percentage. To achieve any kind of significant reduction in energy consumption and CO2 emissions, designers need to think a little further outside the box. Railroad technology provides a perfect analogy.

In the 1970's, in spite of immense infrastructure costs, the electric drive replaced steam traction, which uses locally generated steam to drive the cylinders. These engines were horribly inefficient. Although the exhaust steam was generally reused in auxiliary and ancillary equipment, these measures brought only marginal improvement in the overall energy balance.

Enormous energy losses with hydraulic drives

The pneumatic cylinders widely used in industrial machinery operate on the same fundamental principle as the cylinders of a steam engine. They are used to implement frequently repeating linear movements with short, constant paths. Despite countless improvements to the details of this technology, the overall system efficiency leaves much to be desired. Simply generating the pressurized air in the (usually electric) compressors accounts for 80 percent of the total energy consumption – before the cylinders have performed any work whatsoever. Additional losses are incurred as the air makes its way to the cylinder.

A study performed by the German research organization Fraunhofer shows an average of 25% additional energy lost due to leaks in pipes and valves. With a hydraulic drive, braking energy can't be regenerated. Instead, decompressed air is released. The overall efficiency of a pneumatic axis is therefore lower than 10%.

The cost-effective alternative – Tubular linear motors

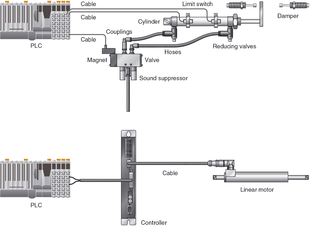

|

| The higher purchasing price of tubular linear motors compared to pneumatic cylinders begins to be balanced out by the reduced complexity of the circuit |

A considerably more efficient alternative to the pneumatic cylinder is a linear motor, which uses electromagnetic forces to convert electrical energy directly into movement. A convenient side effect of linear motors is that, since they lack fluid components, they are much easier to install. This aspect is especially relevant in cases where short linear movements are the only element of the machine that use pneumatics.

Like all electric motors, linear motors are extremely efficient by nature. This fundamental efficiency can be further increased using advanced drive technology such as the ACOPOS servo drives from B&R. These can additionally store braking energy in a DC bus circuit to be used for later acceleration. It is also relatively simple to return excess energy back into the power grid.

However, most linear motors are optimized for applications with more extreme demands on dynamics and precision. When it comes to very simple movements, replacing a pneumatic solution with a linear motor solution is not cost effective. The tubular linear motor, however, is indeed a practicable alternative to the compressed air axis. The stator on a tubular linear motor is located inside a tube, wrapped around the magnets of an armature rod. Its simplified, symmetrical design make it easier to produce than the more well-known flat or U-shaped linear motors. It is cheaper, easier to use and lasts longer, while providing the same effective power.

Cost reduction from 3,000 to 100 euros

"The potential for a real leap in energy savings was brought to our attention by a customer for whom we were calculating the energy consumption of our motors in comparison to a pneumatic system," explains Ernst Blumer, head of sales at NTI AG, manufacturer of LinMot linear motors and servo drives. "This customer needed to move a 15 kilogram load a distance of 400 millimeters at a rate of 30 cycles per minute. Our calculations showed a potential savings of over 90%, which was later confirmed by measurements on the actual system. In this particular application, the energy cost per axis was brought fro 3,000 euros per year down to only 100."

"The potential for a real leap in energy savings was brought to our attention by a customer for whom we were calculating the energy consumption of our motors in comparison to a pneumatic system," explains Ernst Blumer, head of sales at NTI AG, manufacturer of LinMot linear motors and servo drives. "This customer needed to move a 15 kilogram load a distance of 400 millimeters at a rate of 30 cycles per minute. Our calculations showed a potential savings of over 90%, which was later confirmed by measurements on the actual system. In this particular application, the energy cost per axis was brought fro 3,000 euros per year down to only 100."

Replacing the pneumatic cylinder, which is similar in size and shape, can radically reduce the energy consumption of linear axes and provide an exceptionally fast return on investment. The reduction of CO2 emissions is also impressive. In three-shift production, the pneumatic axis in this application emits over 12 tons of CO2 – the equivalent of driving 100,000 kilometers with a modern midsized car.

|

| Only three years after being introduced to the market, the linear motor driven model of the pick-and-place handler developed by German manufacturer electropneumatische Systeme GmbH outsells its considerably lower-priced pneumatic counterpart by 50%. (Source: NTI) |

B&R paves the way for a smooth transition

"It is especially important to us to see our customers benefit from more sustainable solutions," says Bernhard Eder, product manager at B&R. "We've found a very simple way to harness the benefits of this shift in technology and have seamlessly integrated it into our overall system." B&R's ACOPOSmicro servo drives have been given an encoder interface for the 80 VDC series of LinMot linear motors. The Swiss manufacturer's 3x 400 VAC series is already equipped with ACOPOSmulti compatible encoders.

"It is especially important to us to see our customers benefit from more sustainable solutions," says Bernhard Eder, product manager at B&R. "We've found a very simple way to harness the benefits of this shift in technology and have seamlessly integrated it into our overall system." B&R's ACOPOSmicro servo drives have been given an encoder interface for the 80 VDC series of LinMot linear motors. The Swiss manufacturer's 3x 400 VAC series is already equipped with ACOPOSmulti compatible encoders.

Aside from the enormous energy savings, tubular linear motors offer some remarkable functional advantages as well. They can perform several billion strokes before failure, so there is never a need to exchange a cylinder. This lowers maintenance costs and reduces downtime. Tubular linear motors are also well-suited for high frequency applications such as textile machines. Pneumatic drives are incapable of providing the necessary 600 strokes per minute with precision in the hundredth of a millimeter range, nor do they have the necessary durability. Standard linear motors, on the other hand, are too expensive.

Aside from the enormous energy savings, tubular linear motors offer some remarkable functional advantages as well. They can perform several billion strokes before failure, so there is never a need to exchange a cylinder. This lowers maintenance costs and reduces downtime. Tubular linear motors are also well-suited for high frequency applications such as textile machines. Pneumatic drives are incapable of providing the necessary 600 strokes per minute with precision in the hundredth of a millimeter range, nor do they have the necessary durability. Standard linear motors, on the other hand, are too expensive.

ACOPOSmicro servo drives come standard with a LinMot encoder interface for 80 V tubular linear motors, while the 400 V models are controlled by ACOPOSmulti drives. (Source: NTI)

Precision down to the hundredth of a millimeter

The integrated position measurement provides contact-free positioning with a precision down to 0.05 millimeters without causing any mechanical wear. For applications requiring even higher precision, an additional external position encoder can bring the precision into the micrometer range. Integrated sensors send data such as the current stator temperature to the controller for diagnostics and condition monitoring.

The biggest procedural advantage comes from the freedom with which movements can be configured. Stroke length, velocity, acceleration and force can be programmed flexibly. B&R's ACOPOS line of servo drives can be used to implement highly complex movements over the entire stroke. This allows the axis to be adapted to changing conditions, such as workpiece size, or be used for synchronized parallel movements with third-party axes.

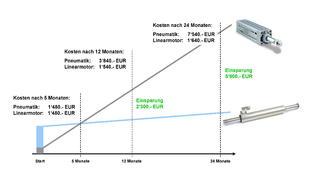

ROI after only 5 months

To this day, the well-known pneumatic and hydraulic technologies continue to dominate when it comes to linear movements. The reason: For machine manufacturers looking at initial investment alone, these solutions appear less expensive than electric drive technology. "With continuously rising energy costs, however, customers purchasing production machines learned long ago to view total cost as the top criteria," says Blumer. Over a production line's entire service life, it can easily become much more expensive to rely on outdated technologies like pneumatics and hydraulics. "In the handling application we mentioned, the higher initial costs were recovered in only five months thanks to the reduction in energy costs, and after two years they're looking at savings of nearly 6,000 euros," continues Blumer. "Large, innovative machine and systems manufacturers are already having the power and air consumption of their machines certified in order to provide their customers a realistic picture of not only the investment costs, but also the operating costs of a system."

To this day, the well-known pneumatic and hydraulic technologies continue to dominate when it comes to linear movements. The reason: For machine manufacturers looking at initial investment alone, these solutions appear less expensive than electric drive technology. "With continuously rising energy costs, however, customers purchasing production machines learned long ago to view total cost as the top criteria," says Blumer. Over a production line's entire service life, it can easily become much more expensive to rely on outdated technologies like pneumatics and hydraulics. "In the handling application we mentioned, the higher initial costs were recovered in only five months thanks to the reduction in energy costs, and after two years they're looking at savings of nearly 6,000 euros," continues Blumer. "Large, innovative machine and systems manufacturers are already having the power and air consumption of their machines certified in order to provide their customers a realistic picture of not only the investment costs, but also the operating costs of a system."

"In addition to energy consumption, replacing hydraulic and pneumatic systems with linear drive technology can also reduce the cost of development, construction and commissioning," adds Eder. "B&R's ACOPOS line offers customers a uniform solution for all types of motion control tasks. They stand to substantially increase the energy efficiency of their machines, whether they use a stepper, torque, synchronous, AC or DC motor or replace a pneumatic axis with a linear drive." And regardless of the task at hand and what type of drive technology is used to accomplish it, B&R's Automation Studio provides a universal development environment for all aspects of motion control.

|

| Automation Studio has a full selection of powerful, integrated tools for positioning tasks. Even the most complex movement sequences can be realized without tedious programming. IEC 61131-3 compliant PLCopen motion control function blocks help simplify and streamline development of motion control applications. |